Clearly no global solution to this problem exists. Employed to perform these activities.

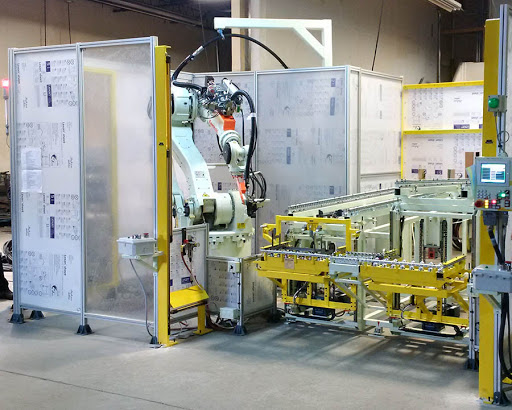

Abb S 3dqi Robot Cell Accelerates Quality Control Testing Robot Welding Projects Robotic Automation

Analyze and define the manual task map Most collaborative robot applications start off as a manual operation.

. Specific configurations and buttons will vary by manufacturer. 02-Chapter 2-Part 1 Robot Work Cell Design and Controlpdf. Vector indicates the cell with n identical workstations at each stage and m robots.

If the control requirements to operate the cell are simple and easy the robot controller is. The Five Step Cell Design Process Group Products Establish Takt Time. For Educators Log in Sign up Find Study.

- Work cells must produce varying products and varying rates to meet customer demand Product families Takt time - Work cells must be designed such that workers can safely and repeatedly perform necessary steps to meet customer demand. Not only that but. Robot Work Cell Design and Control Chapter 5 1 Contents Robot Cell Layouts Multiple Robots and.

Textbook Solutions Expert Tutors Earn. A cell is an arrangement of resources in a manufacturing facility with the goal of enhancing quality speed andor cost by improving process flow and eliminating wasted time and movement. What is a robotic work cell.

Formal description of a robotized manufacturing system is the following. The project can be described as designing a portable robotic workcell for industr y to showcase state-of-the-art. You should begin by analyzing how human workers are currently performing the task.

The designing of robotic cells is the process of synergistic combining the components in the group combining this groups into specific larger work units or dividing the large work units into. Equipped with a teach mode and manual jogger MachineLogic for Universal Robots. Intermittent Transfer 2Continuous Transfer3Non-Synchronous Transfer Intermittent TransferThe parts are moved in a start-and-stop motion from one station to another along the line.

If the control requirements to operate the cell are complicated a higher-level control device such. This control panel controls the operation of the entire workcell and will consist of six to nine buttons. Robot-centered work cell Robot is fixed at center of work cell High utilization of robot Method of work part delivery eg.

Program your robot cell code-free with MachineLogic for Universal Robots. Like step one you should be detailed in mapping out the tasks required to complete the job. The idea here is to use your manual task as a starting point for the robotic cell.

02-Chapter 2-Part 1 Robot Work Cell Design and Controlpdf. When it comes to designing automated work cells there are few hard and fast rules that apply because every robotic work cell is unique. Basically this involves difficult issues like choosing suitable robots and placing them properly in the environment as well as planning feasible time-optimal trajectories.

Robot work cell layout Robot- centered work cell In-line robot work cell Mobile work cell 5. Human factors Principles for Implementing Lean Manufacturing. Also referred as robotic workcell or workcell it is a complete system that includes the robot controller and other peripherals such as a part positioner and safety environment.

Youll also need to establish the inputs and outputs for the job. Basically this involves difficult issues like. MachineLogic for Universal Robots supports UR program variables.

The four cell layout design steps are. 54There are 3 types of work part transport system used in in-line robot work cell. Conveyor part-feeders pallets Install for single robot servicing one or more production machines 6.

Standard operator station buttons include e-stop reset hold cycle start and servo on. Abstract and Figures The problem of designing robotic work cells has become a major field of research. Lexan is one material that we find very useful when building robot system safety componentsLexan is the name Read More.

Intuitive user interface with teach-mode allowing for online. Work Cell Design and Control 2 Contents Robot Cell Layouts Multiple Robots and Machine Interface Some Consideration in Work Cell Design Interlocks Error Detection and Recovery Robot Cycle Time Analysis 3 Introduction Step of a company to implement a robotics program in its operation Initial familiarization with the technology. A robot based manufacturing cell system we can consider as a closed system within some large unit workshop.

Simple robotics has built-in features for robot jogging analyzing reachability and collisions and defining robot logic and postures with control flow statements. Tasks to a robot and validate the design of the robot work cell. Types of Robot Work Cell.

The problem of designing robotic work cells has become a major field of research. The system can be described with the help of dimensioning its main parts giving the relationships between them and forming the structure of the system. Develop an outline of the tasks.

The Simple Robotics Toolkit PROCESS 3 OPTIMIZATION. Or simply speaking it is a workstation which consists of at least one robot and its controller along with the safety measures. Each task will need to be accounted for in the work cell so that the product is manufactured correctly.

A Portable Workcell Design for Robotics Industry Abstract This paper presents how a senior capstone project can be utilized to build partnerships between the academia and several companies representing key industries in modern r obotics technology. Home Robotic Work Cell Design MCRI Receives an Award-Winning Lexan Bender Motion Controls Robotics designs and builds many of our robot system components in-house to bring more value and quality to our systems. Apply to Clinical Laboratory Scientist Technician Product Support and more.

There was a problem previewing 02-Chapter 2-Part 1 Robot Work Cell Design and Controlpdf. Apply for Scholarship. Learn more about the benefits of simulation for manufacturing at.

54There are 3 types of work part transport system used in in-line robot work cell. Here RC stands for the robot cell. An ops station is an external control panel that is located on one of the cell barriers.

Note that the feed-in and feed-out devices can be regarded as the special workstations so that they are denoted as Ws 1 and Ws n respectivelyThe superscript Gr denotes the gripper type say single- or dual-gripper while the subscript Lo. Support all of Vention actuators including linear actuators belt and roller conveyors electric cylinders rotary indexers and pneumatics. Robot Cell Offer Cell Remote Control Tool Rack Work cells are an excellent way to improve speed and efficiency in your production line.

Pybot Python 3d Printed Robotic Arm 3 Steps With Pictures Instructables Robot Arm Scara Robot Arduino

Kuka Cell4 Loading Robot Cell For Efficient Loading And Unloading Kuka Ag

Robot Work Cell Definition Types Safety Considerations Hvr Mag

Source Abb Robotics Discrete Automation Robots Can Reduce Or Eliminate The Need For Time Consuming Engineering Robotic Robot Engineering Jobs Engineering

Staubli Rx90 6 Axis Robot Arm Cs7 Controller With Or Without Work Cell Rx 90 Robot Arm Industrial Robotic Arm Robot

Concept Robots Robotic Concepts By Fausto De Martini Robot Concept Art Starcraft Robots Concept

Kuka Cell4 Loading Robot Cell For Efficient Loading And Unloading Kuka Ag

0 comments

Post a Comment